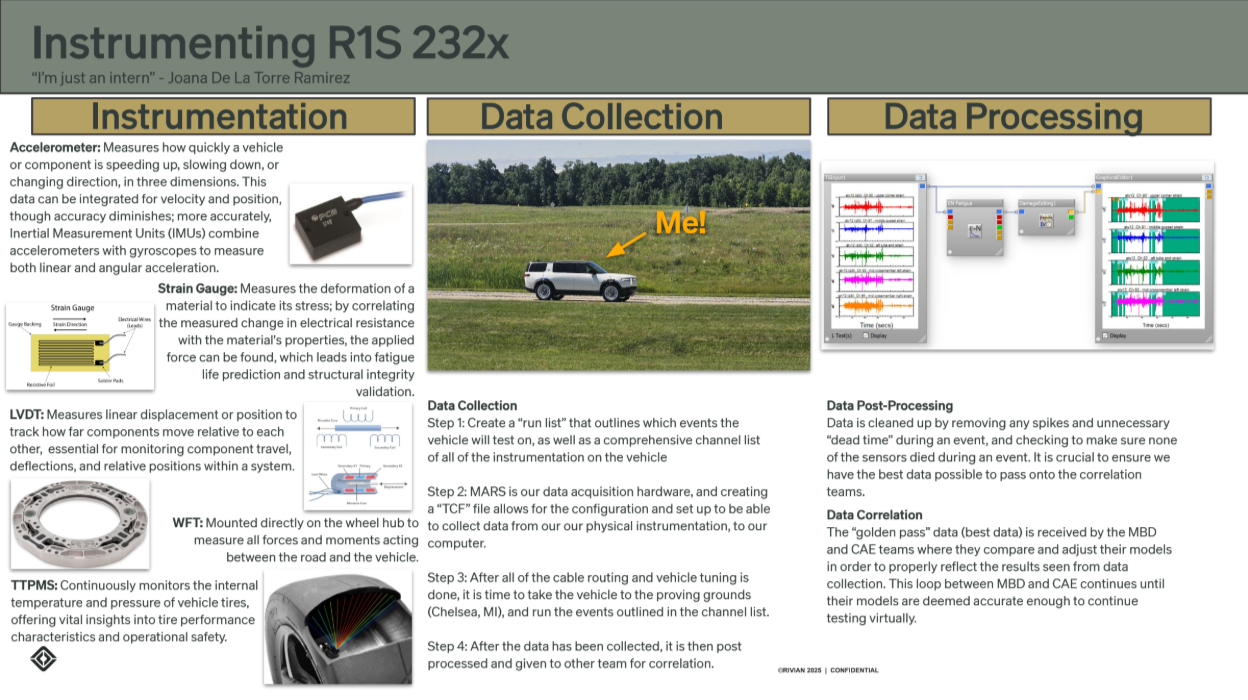

During my internship at Rivian, I worked with the Durability team within the Validation and Verification department, where I supported a full vehicle durability data collection cycle from instrumentation to post-processing. I helped fully instrument test vehicles using wheel force transducers (WFTs), accelerometers, LVDTs, strain gauges, and a temperature and tire pressure monitoring system (TPMS), gaining hands-on experience with the hardware that directly informs durability decisions in vehicle development.

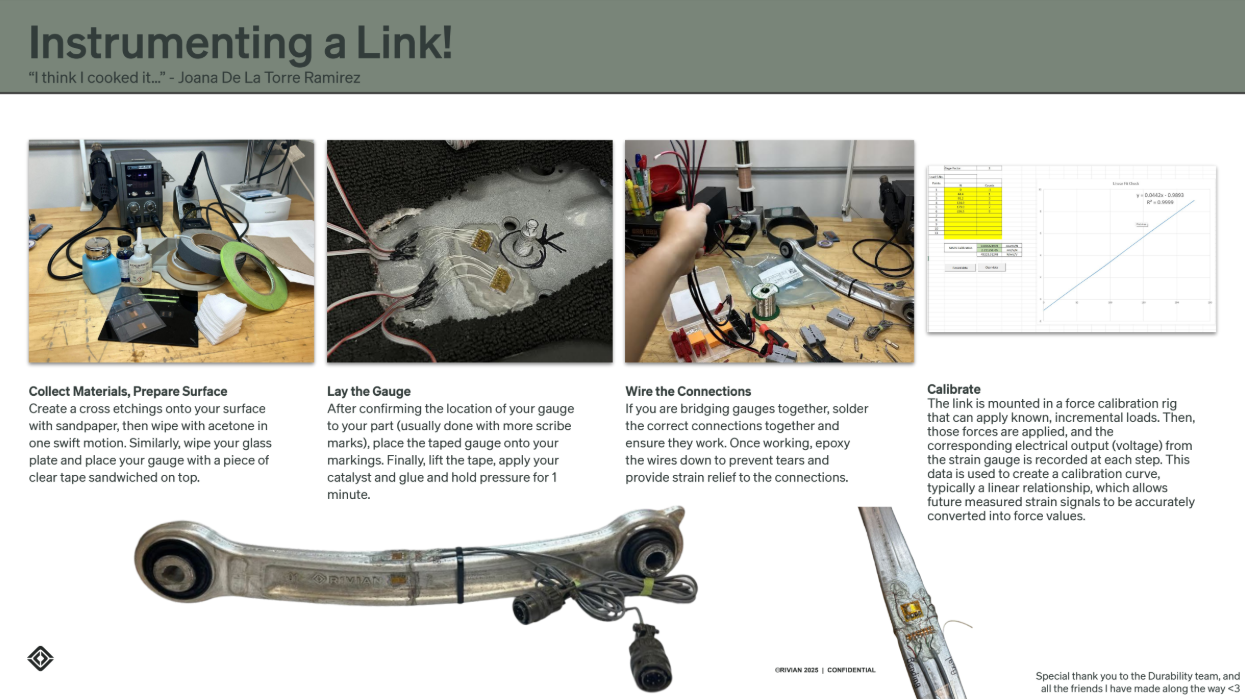

I assisted with on-vehicle instrumentation, calibration, and data collection at the Chelsea, Michigan proving grounds, contributing to real-world durability testing under demanding conditions. In addition to field work, I supported data post-processing using nCode, helping translate raw test data into meaningful insights for durability evaluation. One of the most formative technical experiences of the internship was learning how to design, build, and calibrate my own force transducer for a suspension link, deepening my understanding of load paths, sensor behavior, and measurement accuracy.

Beyond instrumentation and data, I gained valuable hands-on mechanical experience, including independently installing suspension components and torquing hardware to specification—connecting analytical durability work with the physical reality of vehicle assembly. I concluded the internship by presenting my work, learnings, and findings, demonstrating my end-to-end involvement in a durability testing cycle and my growth as a mechanical engineer working at the intersection of testing, data, and vehicle hardware.